-

Email us at:

info@weltreatsystems.com -

Call us on:

020 - 41228334 - Download Brochure

11

Oct 25What Is a Zero Liquid Discharge (ZLD) Plant? Process, Benefits, and Its Role in Sustainable Water Management

- October 11, 2025

A zero liquid discharge plant is a wastewater treatment system that recovers water for reuse and ensures no liquid effluent leaves the facility, converting contaminants into solid residues for compliant handling. In India, such systems are increasingly adopted to meet CPCB/SPCB verification and sectoral charters while reducing freshwater dependency in water‑stressed industrial clusters.

Introduction

India’s industrial growth has intensified water stress and compelled stricter effluent norms, pushing sectors like textiles and distilleries to prioritize high‑recovery reuse over discharge. Zero liquid discharge (ZLD) directly addresses this by recycling permeate back into operations and eliminating liquid outfalls, aligning with basin‑specific regulatory initiatives and court‑driven compliances in key clusters.

What is a Zero Liquid Discharge Plant?

A ZLD plant comprises facilities and systems that enable absolute recycling of treated water and conversion of dissolved pollutants into solids so that no liquid leaves the site. In a textile or pharmaceutical unit, permeate from membranes and condensate from evaporators are reused in utilities/processes, while salts are crystallized and handled under hazardous‑waste authorizations or applicable norms.

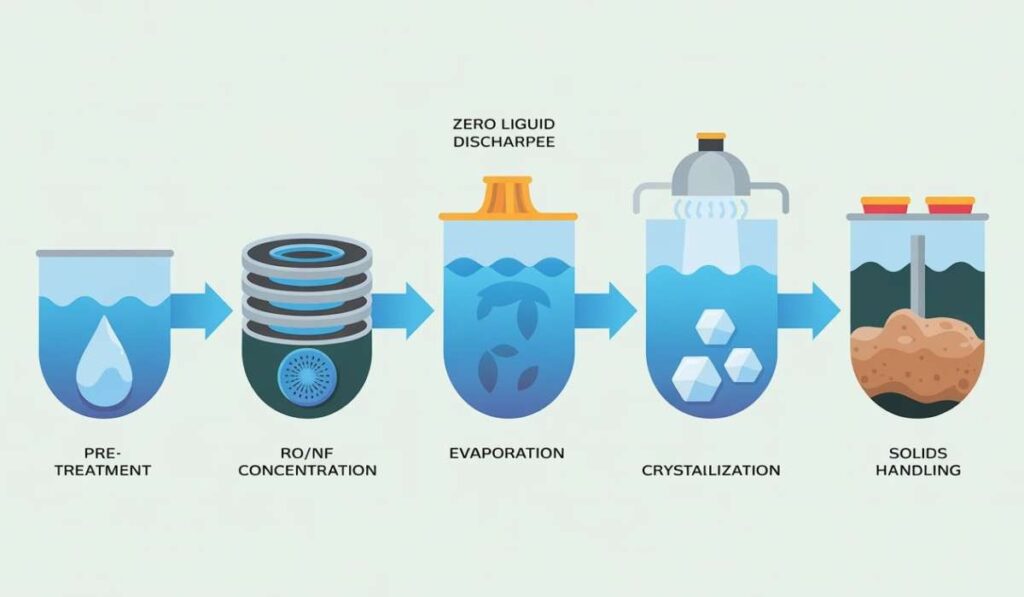

How a Zero Liquid Discharge System Works

- Pre‑treatment: Screening, pH correction, coagulation/flocculation, biological treatment, and media/UF filtration to protect downstream RO and thermal units from fouling and scaling.

- RO/NF concentration: Reverse osmosis or nanofiltration recovers a large fraction of clean permeate and minimizes brine volume before thermal steps, typically forming the core of hybrid ZLD designs.

- Evaporation: Multi‑effect evaporators or mechanical vapor recompression evaporators further concentrate the RO reject and generate reusable condensate, reducing brine to near‑saturation.

- Crystallization: Brine crystallizers convert remaining dissolved solids to crystals; the resulting solids are dewatered and managed per consent and hazardous‑waste rules.

- Solids handling: Filter presses, dryers, and compliant storage/disposal complete the zero‑liquid pathway with continuous monitoring via OCEMS where mandated.

Recovery performance

Well‑engineered ZLD trains typically achieve about 90–95% water recovery, with actual performance depending on feed chemistry, scaling control, and hybrid membrane‑thermal design. Case literature and vendor data across Indian installations consistently cite high recovery ranges when pretreatment and brine management are optimized.

Benefits of Zero Liquid Discharge Water Treatment

- 100% wastewater containment with high water recycling reduces freshwater withdrawals and improves resilience in stressed basins.

- Environmental protection by eliminating liquid outfalls and concentrating pollutants into manageable solids, lowering risk to rivers and groundwater.

- Compliance enablement with CPCB/SPCB schemes, including ZLD verification SOPs and sectoral charters for priority industries and river basins.

- Potential resource recovery of salts and process inputs, depending on effluent chemistry and market feasibility under approved utilization pathways.

Industries Using ZLD Systems

Adoption is prominent in textiles, distilleries, pharmaceuticals, power, tanneries, chemicals, and food processing where discharge is restricted and reuse is valuable. Notably, Tirupur’s textile cluster pioneered ZLD at CETP scale under court directions, demonstrating feasibility and economic revival after compliance adoption.

Challenges and Cost Considerations

ZLD carries higher capex and opex due to energy‑intensive evaporation/crystallization, specialized O&M, and scaling control requirements across variable effluent chemistries. Clusters report operating‑cost adders for wet‑processing value chains, though hybrid MVR/MEE configurations and brine‑reuse strategies can mitigate lifecycle costs.

Future of ZLD in India

CPCB’s SOPs for ZLD certification and sectoral charters, along with continuous OCEMS integration and consent workflows, are formalizing verification and compliance pathways. As Make‑in‑India manufacturing expands and ESG pressures rise, ZLD is set to scale alongside high‑recovery ETP retrofits and industrial water circularity commitments.

Conclusion

Zero liquid discharge plants enable a circular water economy by maximizing reuse and eliminating liquid discharges, aligning with India’s tightening environmental governance and basin‑level protections. With maturing hybrid designs and verified compliance frameworks, ZLD will increasingly anchor sustainable, low‑risk growth in water‑intensive industries.

FAQs

What is the purpose of a Zero Liquid Discharge Plant?

The purpose is to recycle treated water back into operations and prevent any liquid effluent from leaving the site by converting remaining contaminants into solids for compliant handling.

How does ZLD differ from conventional wastewater treatment?

Conventional plants discharge treated effluent to surface water or sewers, whereas ZLD integrates membranes and thermal steps to recover water and crystallize solids so no liquid is discharged.

What are the main stages in a Zero Liquid Discharge process?

Typical stages include pretreatment, RO/NF concentration, evaporation via MEE/MVR, crystallization, and solids dewatering/management with monitoring and reuse loops.

Can ZLD water be reused for industrial applications?

Yes, permeate and evaporator condensate are commonly reused for utilities and processes, with systems often achieving around 90–95% recovery depending on design and feed quality.

What are CPCB guidelines for Zero Liquid Discharge in India?

CPCB issues sectoral charters and a formal SOP for ZLD verification and certification outlining documentation, OCEMS connectivity, mass balances, and technology configurations required to demonstrate ZLD.