-

Email us at:

info@weltreatsystems.com -

Call us on:

020 - 41228334 - Download Brochure

01

Feb 26Why Wastewater Treatment Plants Are Critical for Industrial Operations

- February 1, 2026

- sewage treatment for industries sewage treatment plant compliance Water Treatment

Industrial growth and operational continuity are inextricably linked to responsible resource management.

For plant heads and operations managers, wastewater is not an abstract environmental concern; it is a direct operational, financial, and legal variable.

The era of viewing effluent treatment as an optional, ethics-driven overhead is over.

In today’s landscape of stringent regulations, acute water scarcity, and heightened scrutiny, a functional, compliant Wastewater Treatment Plant (WWTP) is as essential as a reliable power supply.

It is a core component of industrial infrastructure, mandated for survival and critical for sustainable growth.

Ignoring it introduces severe, measurable risks to your license to operate, your balance sheet, and your plant’s long-term viability.

Understanding Industrial Wastewater: Not All Effluent Is the Same

Unlike relatively consistent domestic sewage, industrial effluent is a complex, variable, and often hazardous stream.

Its composition is a direct reflection of your production processes, raw materials, and cleaning protocols.

Treating it effectively requires first understanding its unique genesis and characteristics, as a mischaracterization here leads directly to treatment system failure.

Sources of Industrial Wastewater

- Process Water: Water integrated into manufacturing—used in reactions, washing, extraction, or as a transport medium. This stream often contains the highest concentration of process-specific pollutants.

- Cooling and Boiler Blowdown: While primarily thermal pollution, this water can contain corrosion inhibitors, biocides, and high levels of dissolved salts (TDS) from concentration cycles.

- Cleaning and Washing: Water from equipment wash-down, floor cleaning, and tank cleaning. It can contain oils, fats, solvents, and residual product, creating high organic (BOD/COD) and chemical loads.

- Chemical Byproducts: Includes spillage, leftover batches, and off-spec products often sent to drain. This is a primary source of toxicity and hazardous waste in effluent.

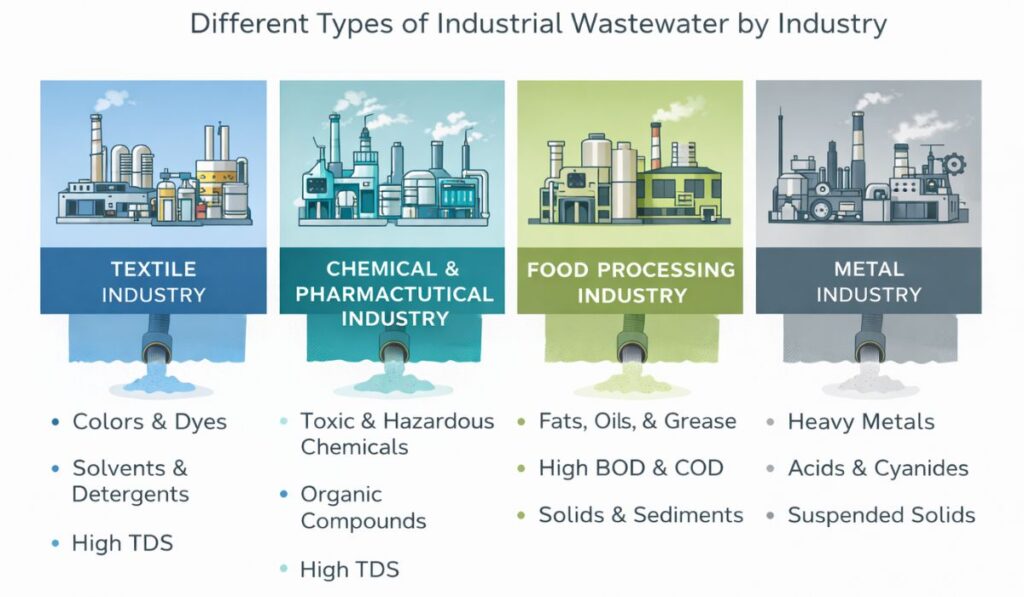

Industry-Wise Wastewater Characteristics

- Textile & Dyeing: Characterized by intense colour, very high COD, heavy metals (from dyes), and variable pH. One of the most challenging effluents to treat to compliance standards.

- Pharmaceutical & Chemical: May contain active pharmaceutical ingredients (APIs), complex organic compounds, solvents, and toxic substances. Requires advanced, often custom-engineered treatment.

- Food & Beverage: High in biodegradable organic matter (BOD), fats, oils, grease (FOG), and nutrients (nitrogen, phosphorus). While more treatable biologically, it requires robust pre-treatment.

- Automotive & Metal Processing: Contains heavy metals (chromium, nickel, zinc), oils, lubricants, and suspended solids from plating, painting, and machining operations.

- Power & Heavy Engineering: Primarily high TDS from demineralization plants, along with thermal pollution and potential oil/grease content.

What Happens When Industries Ignore Wastewater Treatment

The decision to neglect or inadequately manage wastewater treatment is a calculated risk with severe, escalating consequences.

It is a direct threat to operational sovereignty.

Legal and Regulatory Consequences

The Central Pollution Control Board (CPCB) and State Pollution Control Boards (SPCBs) enforce compliance with zero tolerance.

Non-compliance triggers a cascade of actions, as observed across multiple SPCB enforcement drives nationwide. These include show-cause notices and hefty daily penalties.

It can escalate to the revocation of the critical Consent to Operate (CTO), and ultimately, complete plant shutdowns.

Legal prosecution of company directors is also increasingly common.

Once a shutdown order is issued, restarting requires full compliance, paying all fines, and navigating a lengthy, arduous process.

This results in permanent reputational damage with regulators.

Operational and Financial Damage

Untreated or poorly treated effluent corrodes pipelines and infrastructure. Discharging non-compliant water risks immediate stoppage orders.

This causes unplanned and catastrophic production downtime.

The “emergency” cost of hiring tankers, arranging temporary treatment, or paying exorbitant fines far exceeds planned investment.

It disrupts supply chains and damages client relationships.

Long-Term Liability

Effluent contaminates groundwater and soil. This creates a long-term environmental liability that attaches to the land and the company.

Future expansion plans will be blocked. It can lead to protracted legal battles with communities and civil society, resulting in costly remediation orders.

The resulting irreversible brand damage affects market positioning and investor confidence.

Wastewater Treatment as a Production Continuity System

A WWTP must be reframed from a support function to a core production asset. Its primary role is to ensure the continuous, uninterrupted flow of manufacturing.

Just as a failure in the power substation halts the production line, a failure in the WWTP can force an entire facility to stop.

A robust WWTP provides operational stability by creating a closed-loop buffer between volatile production output and rigid regulatory standards.

It decouples production scheduling from the risk of compliance-triggered shutdowns. Furthermore, in regions with erratic municipal water supply or rationing, the water recovery and reuse capability of a WWTP transforms it into a strategic water reservoir.

This directly insulates production from external resource disruptions. It is not merely treating waste; it is actively safeguarding runtime and resource security.

Role of Wastewater Treatment Plants in Industrial Operations

A WWTP is a strategic operational asset integrated into the core production lifecycle.

Compliance with Environmental Regulations

Its primary function is to systematically render effluent compliant with SPCB discharge norms, whether for sewer discharge, surface water bodies, or intended reuse.

A well-documented, consistently performing WWTP ensures audit readiness. It turns a major compliance vulnerability into a demonstrable strength during regulatory inspections.

Water Recovery and Reuse

In water-stressed regions, a WWTP is a strategic water security asset. Treated water can be recycled for cooling towers, boiler feed, washing, or even process applications with appropriate polishing.

This directly reduces freshwater procurement costs and dependency.

It insulates operations from scarcity and pricing volatility, and is the foundational step for achieving Zero Liquid Discharge (ZLD) where mandated.

Operational Stability

A predictable, controlled treatment process delivers consistent effluent quality. This eliminates surprises and allows for stable long-term planning.

It drastically reduces the frequency of emergency interventions and regulatory confrontations, letting management focus on production.

Operational stability in the WWTP translates directly to predictability in production planning, maintenance scheduling, and financial forecasting.

Cost Perspective: Wastewater Treatment vs Cost of Non-Compliance

The financial argument for a proper WWTP is unequivocal.

Capital and Operating Costs (High-Level)

The capital expenditure (CAPEX) covers design, civil works, tanks, machinery (screens, pumps, aerators, filters), instrumentation, and installation.

Operational expenditure (OPEX) includes power consumption, chemicals, skilled manpower, lab testing, and scheduled maintenance.

These are predictable, budgetable costs.

Hidden Costs of Non-Compliance

- Penalties and Fines: SPCBs impose penalties per day of non-compliance, often running into lakhs or crores of rupees.

- Legal and Litigation Costs: Defending against regulatory and civil cases consumes significant management time and legal fees.

- Forced Retrofits: Regulatory directives to install systems under duress are always more expensive and disruptive than planned projects.

- Reputation Damage: Loss of trust with regulators, banks, investors, and the local community has tangible long-term financial impacts.

The conclusion is clear: The lifetime cost of robust, compliant treatment is almost always lower than the catastrophic, unbudgeted cost of non-compliance.

Environmental Impact – From Industrial Liability to Responsibility

From an industrial risk perspective, environmental impact translates directly to liability. Contaminated surface water bodies attract immediate regulatory action.

Groundwater pollution is particularly insidious; it creates a long-term, asset-attached liability that can hinder the sale of the property, complicate securing financing, and trigger mandatory, exorbitantly expensive remediation orders.

On a regional scale, unchecked industrial discharge can lead to the contamination of local aquifers, affecting entire communities and agriculture.

This often results in blanket restrictions or the “blacklisting” of industrial clusters by regulators, punishing compliant and non-compliant units alike.

Responsible management through a WWTP mitigates these liabilities, protecting the company’s physical and financial assets.

It transforms a liability into a managed operational responsibility.

Regulatory Framework Governing Industrial Wastewater (India-Focused)

Role of Pollution Control Boards

The Consent to Establish (CTE) is required before construction, ensuring the proposed project has adequate treatment plans.

The Consent to Operate (CTO) is the operating license, granted and renewed based on adherence to stipulated discharge standards and monitoring requirements.

This is the most critical document for any operating plant.

Sector-Specific Requirements

Many sectors face specific mandates:

- Textile, Pharma, Distilleries: Often under Zero Liquid Discharge (ZLD) mandates in water-scarce zones.

- Common Requirements: Installation of Online Effluent Monitoring Systems transmitting real-time pH, TDS, COD, and flow data to the SPCB. Facilities must maintain logs, conduct self-monitoring, and be prepared for unscheduled sampling and inspections.

Wastewater Treatment Is Not One-Size-Fits-All

Difference Between ETP and STP

An Effluent Treatment Plant (ETP) treats industrial wastewater containing chemical, toxic, or non-biodegradable waste.

A Sewage Treatment Plant (STP) treats domestic wastewater from toilets and kitchens. Using an STP for industrial effluent, or vice versa, guarantees failure.

Importance of Effluent Characterization

Design must begin with comprehensive lab analysis of the effluent over time to understand peak loads, flow variations, and pollutant profiles.

Designing based on assumptions or averages leads to an underperforming system.

Custom Design Over Standard Packages

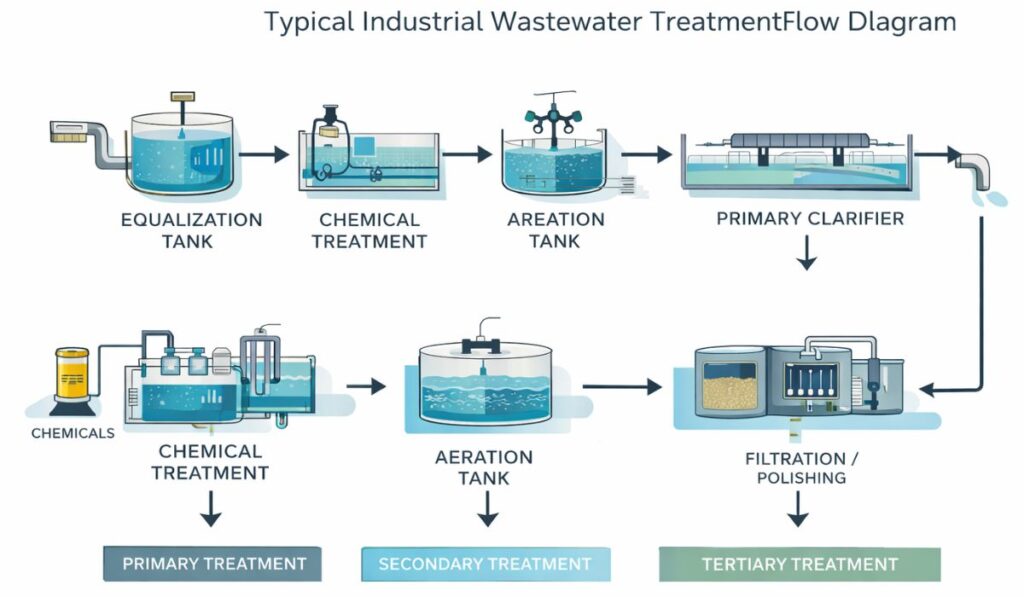

Industrial wastewater requires a custom-designed treatment sequence (e.g., equalization, neutralization, primary treatment, biological/secondary treatment, tertiary polishing).

Opting for cheap, packaged “solutions” without proper design engineering results in chronic non-compliance, frequent breakdowns, and higher life-cycle costs. Scalability for future expansion must be factored in.

Common Mistakes Industries Make with Wastewater Treatment Plants

- Undersized Systems: Designing for average flow, not peak load, causing hydraulic or pollution load overflows.

- Ignoring Operations & Maintenance: Treating the WWTP as a static installation, not a dynamic process requiring daily oversight, spare parts, and preventive maintenance.

- Lack of Trained Operators: Assigning treatment plant operation as a secondary duty to an untrained worker, leading to poor process control and system failure.

- Vendor Selection Based Only on Price: Choosing the lowest-bid vendor without evaluating design expertise, quality of components, and lifecycle service support.

- Poor Monitoring: Not conducting daily in-house checks on key parameters (pH, settling) and relying solely on quarterly external reports, losing all process control.

Long-Term Benefits of a Well-Designed WWTP for Industries

- Compliance Confidence: Uninterrupted operations with peace of mind regarding regulatory requirements.

- Lower Water Dependency and Cost: Significant reduction in freshwater purchase through recycling.

- Predictable Operational Costs: Controlled OPEX versus unpredictable penalty-driven costs.

- ESG and Audit Readiness: Strong documentation and performance supports Environmental, Social, and Governance (ESG) reporting and satisfies investor due diligence.

- Support for Future Expansion: A robust treatment capacity and compliance history smooths the approval process for capacity expansion.

Conclusion

For industrial decision-makers, the imperative for a functionally effective wastewater treatment plant is grounded in operational reality, not environmental advocacy.

It is a fundamental safeguard against regulatory action, financial penalty, and reputational harm.

A well-engineered, properly operated WWTP is a strategic investment that secures your consent to operate, mitigates long-term risk, and turns a compliance mandate into an opportunity for resource efficiency and operational resilience.

In the calculus of modern industry, wastewater treatment is not a compliance checkbox. It is a non-negotiable condition for operating, expanding, and surviving in a regulated, water-stressed economy.