-

Email us at:

info@weltreatsystems.com -

Call us on:

020 - 41228334 - Download Brochure

06

Nov 25Why India Needs Water Recycling Plants – Challenges & Opportunities

- November 6, 2025

India stands at a critical point in its water journey. With a population exceeding 1.4 billion and rapidly growing industries, water demand is rising faster than supply. Yet, according to the Central Pollution Control Board (CPCB), only about 30% of India’s wastewater is treated, and even less is reused. This massive gap highlights why setting up a water recycling plant in India is no longer optional—it’s essential for sustainability, industry growth, and environmental balance.

The Current Water Scenario in India

India generates nearly 72,000 million litres per day (MLD) of wastewater, but only around 26,000 MLD is treated. The remaining untreated wastewater often finds its way into rivers and groundwater, polluting ecosystems and creating public health risks.

Rapid urbanisation, industrialisation, and agricultural expansion have intensified the water stress. Cities like Delhi, Mumbai, Chennai, and Bengaluru face periodic shortages, forcing authorities to explore alternative sources such as wastewater recycling and greywater reuse.

However, the infrastructure gap remains huge. Many treatment plants suffer from poor operation and maintenance, outdated technology, and lack of skilled manpower. To achieve true sustainable water management, India must invest in large-scale and decentralised wastewater recycling plants capable of converting sewage and effluents into reusable water.

What Is a Water Recycling Plant?

A water recycling plant is a specialised facility that treats wastewater so it can be safely reused for industrial, agricultural, or even domestic applications.

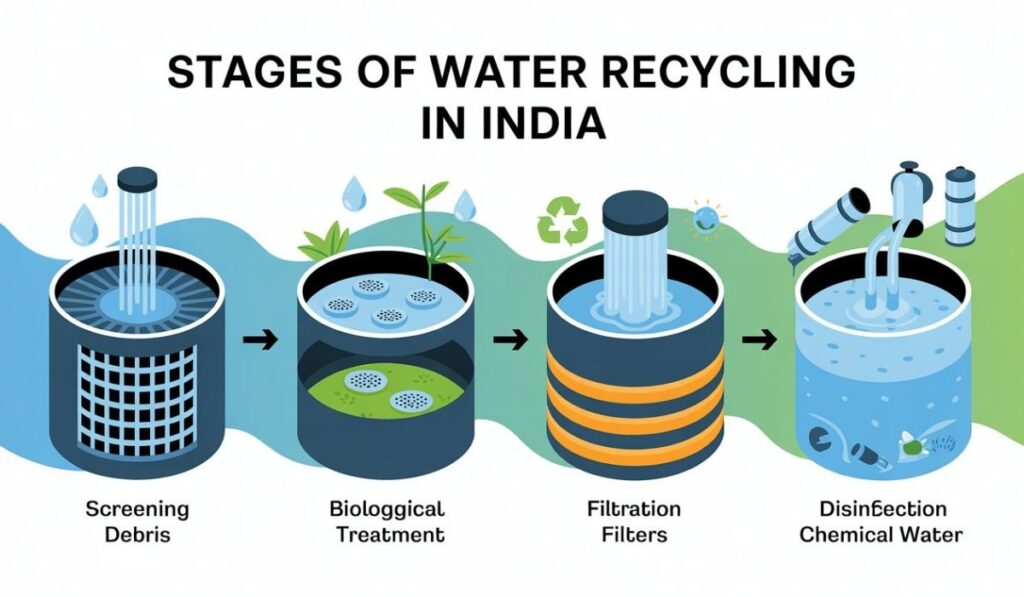

The process generally involves several key stages:

- Screening and Primary Treatment: Removes large solids, plastics, and debris from wastewater.

- Biological Treatment: Uses microorganisms to break down organic matter, typically through processes like MBBR (Moving Bed Biofilm Reactor) or Activated Sludge Process.

- Filtration and Advanced Treatment: Removes suspended particles and nutrients using sand filters, membranes, or reverse osmosis (RO).

- Disinfection: Kills harmful pathogens using chlorine, ozone, or UV systems, ensuring water is safe for reuse.

The treated water can then be used for industrial water reuse, cooling towers, landscaping, construction, or even agricultural irrigation—reducing freshwater dependency significantly.

Key Drivers for Water Recycling in India

Several factors are pushing India toward rapid adoption of water recycling systems:

1. Industrial Water Reuse

Industries such as textiles, power, food processing, and pharmaceuticals generate vast volumes of wastewater. Setting up an Effluent Treatment Plant (ETP) or a Sewage Treatment Plant (STP) enables them to recycle and reuse water, lowering costs and ensuring regulatory compliance.

2. Agricultural and Urban Demand

Nearly 80% of India’s freshwater is used for agriculture. Recycled water from wastewater treatment can meet non-potable irrigation needs, reducing stress on groundwater and river systems.

3. Government Initiatives

The Indian government has launched several initiatives promoting sustainable water management—including the Namami Gange Mission, AMRUT 2.0, and Smart City Projects. These programs encourage municipalities to install STP and ETP systems to improve wastewater reuse rates.

4. Corporate Sustainability and ESG Goals

Businesses today are aligning their operations with Environmental, Social, and Governance (ESG) goals. Implementing a wastewater recycling plant supports these objectives while demonstrating environmental responsibility and long-term cost savings.

5. Urban Infrastructure Growth

With over 100 smart cities planned, decentralised sewage treatment and effluent recycling systems are becoming critical components of modern urban design.

Major Challenges in India’s Wastewater Recycling Sector

Despite progress, several challenges slow down India’s wastewater management efforts:

1. Funding and Financial Barriers

Setting up a water recycling plant in India requires significant investment. Many municipal bodies and small industries lack the funds for installation and maintenance.

2. Technological Gaps

Several plants still rely on outdated technologies that fail to meet the required discharge standards. Lack of adoption of advanced systems like MBR (Membrane Bioreactor) and RO (Reverse Osmosis) limits efficiency.

3. Operational Inefficiencies

Many treatment plants run below capacity due to poor operation and maintenance (O&M) practices and insufficient technical expertise.

4. Awareness and Policy Gaps

Public awareness about greywater reuse and industrial water recycling remains low. Policies for mandatory reuse percentages are still evolving across states.

Despite new investments and initiatives, India still lacks efficient wastewater treatment coverage, especially in tier-2 and tier-3 cities.

Opportunities & Future Potential

The future, however, looks promising. The Indian water treatment market is projected to grow at over 9% CAGR between 2025–2030, driven by industrial growth and stricter pollution norms.

Emerging technologies like MBBR, MBR, and RO-based effluent recycling systems are transforming the sector. Many new projects are integrating smart automation and IoT monitoring to improve efficiency.

Cities such as Chennai and Surat have already set examples. The Koyambedu plant in Chennai treats over 45 million litres of sewage daily and supplies recycled water to industries. Similar models can be replicated across other industrial zones.

Furthermore, the National Water Policy and Atal Mission for Rejuvenation and Urban Transformation (AMRUT) encourage private sector participation, opening new business opportunities for technology providers and consultants.

This makes now the ideal time for industries and municipalities to invest in modern wastewater recycling plants to ensure both sustainability and profitability.

Role of Weltreat Systems in India’s Water Recycling Mission

Weltreat Systems is among the emerging leaders in wastewater and effluent treatment in India. The company provides end-to-end water recycling solutions, from STP and ETP system design to turnkey installation and long-term O&M services.

Their approach focuses on:

- Custom-designed systems: Tailored solutions for municipal, residential, and industrial clients.

- Advanced technologies: Use of MBBR, MBR, and RO systems for higher efficiency and lower footprint.

- Energy-efficient operations: Optimised aeration, automation, and control systems reduce running costs.

- Sustainability focus: Helping clients achieve zero liquid discharge (ZLD) and water reuse compliance.

By partnering with Weltreat Systems, clients gain access to reliable, efficient, and eco-friendly wastewater solutions that contribute to India’s broader sustainability goals.

Conclusion: The Way Forward

India’s future water security depends on how effectively we manage and reuse what we already have. Establishing efficient water recycling plants in India is no longer a choice—it’s a necessity.

Industries, municipalities, and communities must work together to build infrastructure that supports wastewater recycling, greywater reuse, and sustainable water management.

To design or upgrade your water recycling plant in India, contact Weltreat Systems today for a free consultation.

FAQs on Water Recycling Plants in India

1. What is the cost of a water recycling plant in India?

Costs vary based on capacity, technology, and application, but small-scale STPs start around ₹10–15 lakh, while industrial-scale plants can exceed ₹1 crore.

2. How does industrial water recycling work?

It involves treating effluent through biological and chemical processes, filtering it, and disinfecting it for reuse in cooling, cleaning, or manufacturing.

3. What are STP and ETP systems?

STP (Sewage Treatment Plant) treats domestic wastewater, while ETP (Effluent Treatment Plant) handles industrial effluents. Both aim to recycle and reuse treated water.

4. Can recycled water be used for agriculture?

Yes. Properly treated wastewater is safe for irrigation, reducing dependency on freshwater and improving crop yield.

5. Why should industries invest in wastewater recycling?

It helps save operational costs, ensures compliance with pollution norms, supports ESG goals, and contributes to India’s water security.