-

Email us at:

info@weltreatsystems.com -

Call us on:

020 - 41228334 - Download Brochure

08

Nov 25India’s industrial growth is accelerating—but so is its water pollution. Every day, factories and manufacturing units generate millions of litres of wastewater that, if left untreated, can damage rivers, soil, and ecosystems. According to the Central Pollution Control Board (CPCB), over 60% of India’s industrial wastewater is discharged without proper treatment.

This growing concern has placed STP and ETP systems (Sewage Treatment Plants and Effluent Treatment Plants) at the heart of India’s sustainable water management strategy. Today, these technologies are not just tools for compliance—they are essential investments for efficiency, recycling, and environmental responsibility.

Understanding STP and ETP Systems

Both STP (Sewage Treatment Plant) and ETP (Effluent Treatment Plant) are designed to clean wastewater, but they serve different purposes:

- STP (Sewage Treatment Plant):

Treats domestic wastewater—such as water from toilets, bathrooms, kitchens, and canteens—coming from residential, commercial, or institutional sources. - ETP (Effluent Treatment Plant):

Handles industrial wastewater that may contain harmful chemicals, oils, metals, and organic matter. It is specifically designed to treat process water from industries like textiles, food processing, pharmaceuticals, tanneries, and refineries.

Together, STP and ETP systems form the backbone of industrial wastewater treatment in India, ensuring that polluted water is treated, recycled, and reused safely.

How These Systems Work

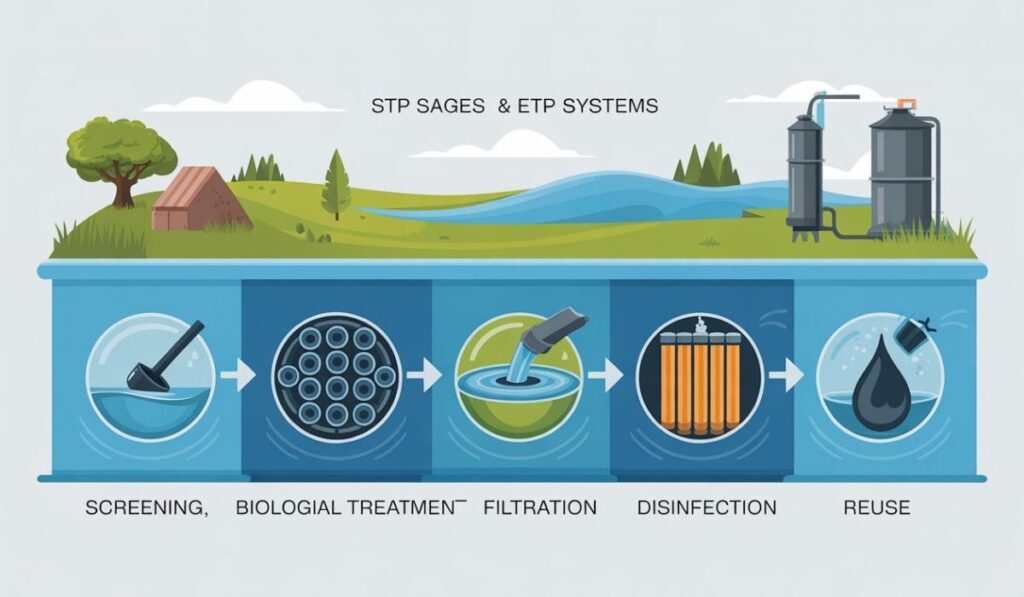

The process of wastewater treatment typically involves several key stages, combining physical, biological, and chemical methods.

1. Preliminary and Primary Treatment

Large solids, plastics, and debris are removed through screening and sedimentation. This step prepares the water for further treatment.

2. Biological Treatment

Microorganisms break down organic matter in wastewater. Popular technologies like MBBR (Moving Bed Biofilm Reactor) and MBR (Membrane Bioreactor) improve efficiency and reduce energy consumption.

3. Secondary and Tertiary Treatment

Advanced filtration and disinfection systems (such as sand filters, UV, or chlorine) remove fine particles, pathogens, and dissolved impurities.

4. Sludge Handling and Disposal

The sludge generated is treated and disposed of safely, or reused as compost in some cases.

5. Water Reuse and Recycling

The treated water is often reused for industrial processes, cooling towers, landscaping, and toilet flushing, significantly reducing freshwater demand.

This cycle makes STP and ETP systems vital for achieving zero liquid discharge (ZLD) and ensuring sustainable water management.

Why Industries Need STP and ETP Systems

1. Regulatory Compliance

Pollution Control Boards across India mandate all industries to install and operate treatment systems. Non-compliance can lead to fines, closures, or suspension of operations.

2. Cost Efficiency

By reusing treated water, industries cut down on their freshwater bills and reduce dependence on municipal supply. Over time, STP and ETP plants pay for themselves through savings.

3. Environmental Protection

Treated effluents reduce the contamination of rivers, lakes, and groundwater, safeguarding biodiversity and public health.

4. Sustainability and ESG Goals

With growing awareness around Environmental, Social, and Governance (ESG) reporting, industries are now investing in wastewater recycling plants to align with global sustainability standards.

5. Brand Image and Corporate Responsibility

Adopting wastewater recycling practices strengthens a company’s reputation as an eco-conscious, responsible brand.

Technological Advancements Driving Change

The wastewater treatment landscape in India is evolving fast. Traditional treatment methods are giving way to smart, energy-efficient, and compact systems.

Some of the notable technologies include:

- MBBR (Moving Bed Biofilm Reactor): Efficient for high-load industrial effluents.

- MBR (Membrane Bioreactor): Produces high-quality treated water suitable for reuse.

- SBR (Sequential Batch Reactor): A flexible system ideal for space-constrained industrial sites.

- RO (Reverse Osmosis): Used for advanced filtration and effluent recycling in ZLD applications.

In addition, many modern STP and ETP systems integrate automation and IoT-based monitoring, allowing remote tracking of performance and ensuring consistent water quality.

India’s Regulatory Push and Market Potential

India’s government has strengthened environmental laws under the Water (Prevention and Control of Pollution) Act and the Environmental Protection Act. Recent amendments require all new industrial units to include wastewater treatment and reuse plans in their design stage.

Government programs like Namami Gange, AMRUT 2.0, and Smart City Mission are also driving the adoption of decentralized wastewater recycling plants.

According to recent industry reports, the Indian wastewater treatment market is projected to reach USD 10 billion by 2030, growing at a rate of around 9–10% annually. The rising demand for industrial water reuse and effluent recycling is a major contributor to this growth.

Real Success: A Look at Chennai and Surat

Cities like Chennai and Surat are leading examples of wastewater reuse.

- Koyambedu Plant, Chennai: Treats over 45 MLD (million litres per day) of sewage and supplies recycled water to nearby industries.

- Surat Municipal Corporation: Recycles treated water from its sewage plants for industrial use, saving crores of litres of freshwater every year.

These projects showcase the potential for public-private partnerships and highlight how recycling wastewater can secure India’s water future.

The Role of Weltreat Systems

At the forefront of this transformation is Weltreat Systems, a trusted name in water and wastewater management solutions.

The company offers end-to-end expertise in:

- Design and installation of custom STP and ETP systems

- Turnkey project execution for industrial and municipal clients

- Upgradation and retrofitting of existing treatment plants

- Operation & Maintenance (O&M) support for long-term efficiency

- Integration of advanced MBBR, MBR, and RO-based technologies

Weltreat Systems focuses on innovation, reliability, and sustainability—helping clients move toward zero discharge, lower costs, and environmental compliance.

Whether it’s a small-scale STP for a housing society or a large ETP for a manufacturing plant, Weltreat delivers tailor-made, cost-effective, and eco-friendly solutions.

Challenges Still Ahead

Despite the progress, a few challenges persist in India’s wastewater sector:

- Limited awareness about reuse potential

- Poor operation and maintenance in municipal systems

- Lack of skilled manpower

- Need for stronger financial incentives for recycling projects

However, with modern technologies, growing environmental consciousness, and expert partners like Weltreat Systems, these challenges can be overcome.

Conclusion: Building a Water-Secure Future

India’s path to sustainability depends on how wisely it manages and reuses water. STP and ETP systems are not just regulatory necessities—they are strategic assets for industries and cities alike.

Adopting efficient wastewater treatment and recycling plants ensures cleaner rivers, reduced freshwater stress, and a greener future for the next generation.

To design, upgrade, or maintain your STP or ETP system in India, contact Weltreat Systems today for a free consultation.

FAQs: STP and ETP Systems in India

1. What is the difference between STP and ETP systems?

STP treats domestic wastewater, while ETP handles industrial effluents containing chemicals and heavy metals.

2. How much does an STP or ETP plant cost in India?

Cost varies by capacity and technology—small units may start from ₹10–15 lakh, while large industrial systems can exceed ₹1 crore.

3. Can treated water be reused for industrial purposes?

Yes. Properly treated water is often reused in cooling towers, boilers, landscaping, and flushing systems.

4. What technologies are most effective for wastewater recycling?

MBBR, MBR, and RO systems are currently the most efficient and widely adopted technologies in India.

5. Why should industries invest in wastewater treatment?

It ensures compliance with pollution norms, saves water costs, supports ESG goals, and protects the environment.